Specific adsorbents for clean biodiesel

Biodiesel contains mostly still wax-like plant components which impair the quality of the fuel. These can crystallise during storage and are thought to block the fuel filter. Researchers at the Fraunhofer Institute for interfacial Engineering and Biotechnology IGB in Stuttgart has developed specific nano-particles which bind these unwanted accompanying substances.

Vegetable oils from regenerating raw materials such as rape and soy are increasingly converted to biodiesel. Fat-soluble components of the vegetable cell membrane, acetylated sterylglycoside are already in the oil in the oil mill. As so valuable as these plant materials are for human nutrition, as so unwanted are they in the biodiesel. In its production, during the transesterification of the triglyceride of the oil to Methyl ester, the accompanying substances lose their acetyl side chain. In contrast to the acetylated form, the resulting Sterylglycoside has very low solubility in biodiesels and crystallises during storage. As these crystals are very small, they are suspected of causing blockages in the fuel filter. Up until now it has not been possible to determine a statistically provable interaction between Sterylglycoside content and filter blockage. Bio Diesel manufacturers are, however, searching for a way to selectively remove the unwanted plant materials from the oil and/or biodiesel.

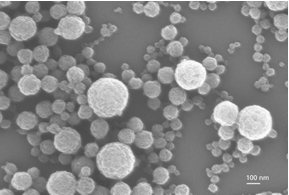

In one of the projects promoted by the Union zur Förderung von Oel- und Proteinpflanzen e.V. (UFOP) researchers at the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB in Stuttgart have been able to manufacture nanoscopy sized polymer particles with selective binding sites for one of these accompanying substances. In the NANOCYTES© procedure patented by Fraunhofer, suitable appearing monomers were mixed with so-called cross-linkers. These ensure that monomers chemical components cross-link themselves into tiny polymer balls with a dimension of only 200 to 300 nanometres. During the polymerisation process the substance to be removed, is added as characteristic part of the acetylated Sterylglycosides, so that this is “inserted” on the surface of the developing plastic balls. These print molecules are extracted from the particles in a subsequent step. A chemical negative imprint remains on the particles - as highly selective binding site for Stigmasterol.

In the context of this project the first attempts demonstrated that amongst the different adsorbent particles made of different monomers and cross-linkers there were those which selectively bind Stigmasterol. The researchers were thereby able to demonstrate that Stigmasterol was better bound by imprinted particles than by unprinted particles, which were otherwise manufactured in the same way.

With this project it was able to be proven that this principle functions. The researchers therefore propose to examine this removal principle in the context of a follow-up project with specific adsorbent particles which can also bind Stigmasterol Sterylglycosid from material biodiesel - or acetylated Stigmasterol Sterylglycosid from vegetable oil.

Since the polymer particles removed from the biodiesel are extremely stable and robust, these would then be of excellent use in a technical process. Packed as packing materials in a column or as selective layer in membranes, they could intercept the unwanted accompanying substances like a filter. And as the adsorbent substances dissolve again with a change of the solvent, the adsorbent particles would perhaps be re-useable.

The UFOP and the Fraunhofer Institute hope the results of these preliminary examinations have aroused the interest of the oil mill and biodiesel industry in an appropriate follow-up project.

The final report of the project can be downloaded here.

These particles specifically adsorb acetylated Stigmasterol Sterylglycoside. © Fraunhofer IGB.

Union zur Förderung von Oel- und Proteinpflanzen E.V.

Union zur Förderung von Oel- und Proteinpflanzen E.V.